Skier and cover photo: Leland Kirton

Riding photos: Taylor Kirton

Words and ski pictures: Grant Wall

Early on in my ski building game I knew I wanted my skis to have a few key characteristics. Quality and durability were at the top of the list, and respectively so as the two go hand in hand. But still being a very inept builder I had to learn what would give my skis longevity. To get the best education on this matter I had to bite the bullet and build a pair of skis to be destroyed, and yes, it is just as painful as it sounds.

Not having access to any fancy destructive testing equipment I turned to a more practical test environment well known for butchering skis, the park. However I am no hot ryder; and the thought of destroying my own skis cuts pretty deep. So to get unbiased testing I had to look for a well seasoned park rat to punish my skis. Enter my good buddy Leland, a very competent shredder who had more than proven his willingness to abuse some skis as he snapped his last pair throwing some big disasters during the 2012-2013 spring season.

Yeah, I don't think that is an intentionally inconsistent flex pattern. I know just the guy to replace these.

Since these skis would be piloted by Leland, I took his wants into consideration while designing them. The end result was a soft and buttery long length park ski dubbed the 'Paperclip'. The specs are stated below.

Shape Profile:

120MM Tip/ 88MM Waist/ 116MM Tail, 184CM Length.

Base Profile:

70MM Tip Height, 9MM Tip Rocker/ 2MM Camber/ 65MM Tail Height, 9MM Tail Rocker.

Core Profile:

2.5MM Tip Thickness/ 11MM Waist Thickness/ 2.5MM Tail Thickness, The core has a maple center, pine exterior and epoxy coated pine sidewalls.

Materials:

2001 Grade, clear PTEX base.

PTEX white tipspacers and clear PTEX (electrical tape graphics) topsheet.

22 Oz. Tri-axial fiberglass.

Entropy room temperature cure epoxy.

22mm VDS rubber placed along the edges.

2.2MM x 1.9MM steel edges.

A few notable things about their construction. Firstly my choice against using some kind of PTEX or ABS plastic sidewall. Sidewalls add some complication to the manufacturing process that I didn't feel ready to face; and my previous few skis I built have all been constructed with wood sidewalls with a high degree of success. So this was a great chance to test the durability of epoxy coated pine sidewalls compared to PTEX or ABS found on most of today's skis. Secondly, I chose to use a clear topsheet and clear base. I personally find the look pretty damn sexy, but it serves a higher purpose. It gives us the chance to look at each component inside of the ski and how they're interacting with each other.

Fast forward to now after the skis have been on snow since our late start to the season in mid December. They've seen a great mix of everything at the local park and even more at Leland and his bro's yard setup. Leland has a very well rounded skiing game so his time is evenly distributed across most of the features he has access to in a day. Watching him I've been nervous as hell, but getting to see him throw down is really part of the satisfaction; I feel like a proud father of sorts. However, the skis went onto his feet as a flawless set, and to say the least they haven't come back quite so. And with the skiing I had seen that was definitely to be expected.

Hard On Park, a state of the art testing facility.

Living true to it's name, the backyard jib oasis is hard on skis...

With the skis back in my hands for a while I've had the chance to inspect them really well and document the damages. All of the damage is largely varying and covers off a lot of the blows you would typically see on well ridden park skis. Below is a breakdown of all of the broken down areas on the Paperclips.

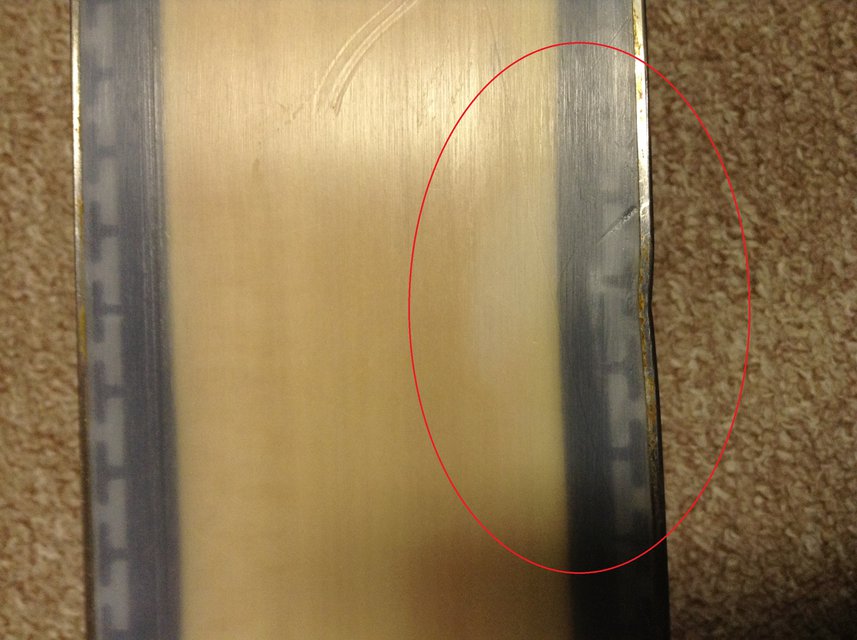

Delaminations:

When the layers inside of a ski break their epoxy bond between each other and separate we get what is known as a delamination. Looking through the clear base and topsheet this is easily defined by the bright white blotches inside the ski. The top two pictures are considered edge delaminations and if you've ever had an edge come out of your ski before, this is what the onset of a pullout looks like. For the most part edge delams initially occur from rail and jib impacts.

But that is only part of the reasoning why edges twist out of skis. When a ski is flexed all of the ski's materials bend at different radii from each other and try to shear apart the thin layer of epoxy that sticks them together. So with time the edge delams will grow bigger with heavy and repeated flexing of the ski, ultimately leading to huge sections hanging out. To help slow that fatigue on the bonding, thin black rubber strips have been put in place to help mitigate this shearing action between the edge and the rest of the ski. Unfortunately, there isn't much that can be done to fix these little bubbles, So we will just have to keep an eye on the Paperclips and watch the edges slowly peel free.

The delams in the set of pictures below are tougher to see than the ones about so I've circled them in red. In the shot directly below, the cause is very apparent; the bent section of edge caused by a rail impact has pushed some surrounding base material away from the core. This isn't terribly crucial because it is just behind the ski's heelpiece where the core is pretty thick. This is another delam that cannot be repaired but if isn't a cause for concern in the first place, then why bother worrying.

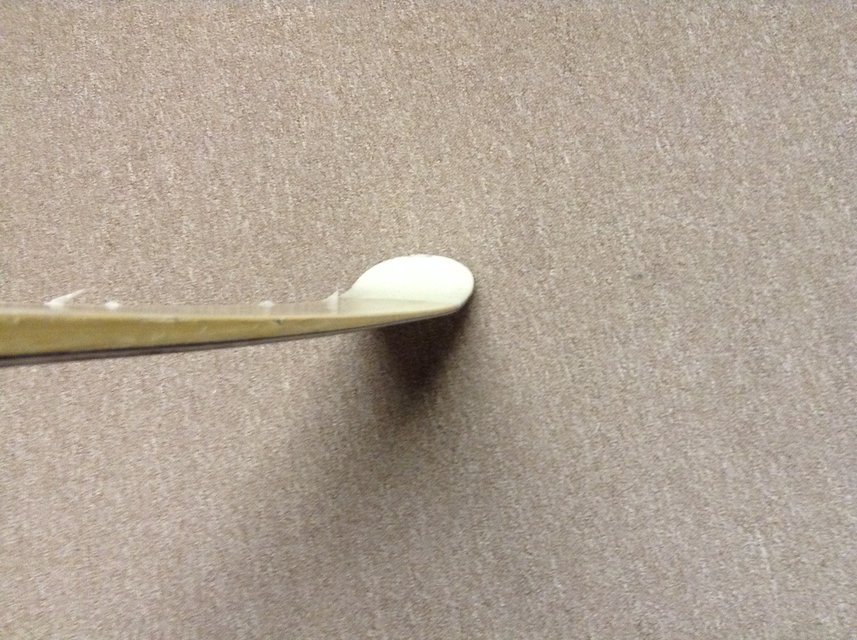

The next little patch is located very close to one ski's tip. I am guessing that this separation was a result from a dirty spot on some materials before the ski was pressed, creating a poor bond in the first place. And with these skis largely being used as the buttering machines they are, any reasonable amount of bending stress would force the point of weak adhesion apart. At least with being a contaminated spot, the areas around the blotch should keep a pretty strong bond. If this does grow any more though the core will no longer have it's full support and it may cause the wood to weaken and snap. And being in such a thin area, there is a reasonable chance of that happening.

Splinters and Cracks

Again, one of the unique things about the Paperclip's construction compared to most consumer skis were my choice to use epoxy coated pine sidewalls. One of the things I noticed about the skis is that each ski had a torn up sidewall on one side while the other sidewall was immaculate. This is a pretty clear indication that the skis are being rode on the same feet all the time. The pictures speak for themselves; down the page you will see identical lengths of sidewalls from two different skis.

This splintering was fairly expected after seemingly endless switchups were carried out on the skis. But the one thing that caught me off guard was a fairly big crack running a few millimeters into the sidewall and core. Splinters themselves are portions of wood getting sliced, gripped, and cracked away. So with time the splintered portions will leave a high stress area along the sidewall; and any of these spots within the binding area where all of the skis forces are transferred from the rider to the snow are fairly prone to propagating a nice big crack. Luckily I should be able to inject some epoxy into this crevasse to slow it's progression into and along the core. Admittedly, I don't have a very optimistic outlook on how well a repair like that will hold up.

Despite how bad some of these damages may seem they're nothing short of what we might see from a pair of well ridden consumer park skis that have been on snow for a similar amount of time. The insight I've had from this look inside has directed my attention to a few things so I can up the quality and durability factor of my future skis. The edge delams could be fixed by using a heat cure epoxy that produces a stronger bond between materials. The nasty edge dent and resulting delamination could also be fixed by switching to a beefier edge that can handle burly impacts. Sidewalls, I definitely need to overcome the manufacturing challenges associated with ABS or PTEX sidewalls so I can incorporate them into my sticks. Once I make the switch I really think I'll be producing on a level that most manufacturers do today which I would be stoked on. And damn, colored sidewalls look pretty cool to.

So I'll give these skis some decent tune, then get them back under Leland's feet for another session of punishment. What that havoc might bring to them? I think we'll probably see more of the above. Who know's maybe I'll report back with them in multiple pieces; a hard guess to make. If there is one thing that the session is guaranteed to deliver, a shitload of nervous hear beating from myself.

Buttering it outta here!

Comments