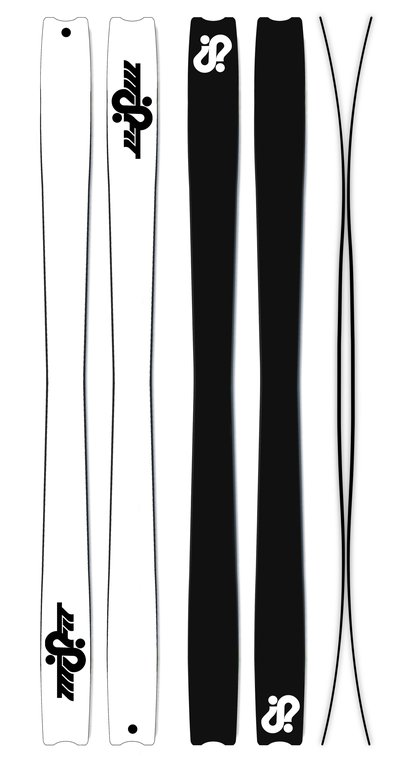

HypeBeastSome other stuff from my adhd. Why is there a dot under the S? I get it for the initial "i" but man is that bothering me.

Google can't find you. I stopped looking after 50 results.

Are they measured before or after pressing?

Who makes the sintered base?

Yay on listing specs and construction stuff. I can't stand when companies leave this shit out... especially turn radius, like @VISHNU neglects to include 👀

That black topo background on your website would look sick as a topsheet

Nice price point if these pan out as decent skis.

The S in the logo is comprised of two question marks, that shape is our secondary logo that will be used for base cutouts, apparel etc.

Google doesn't recognize us yet off a search as the website is so new and I am still figuring out search engine optimization, might just have to throw some money at google.

We measure before pressing, and the prototypes are noticeably longer than other skis we own at the same "length".

The production model will use isosport base and our hand builds will most likely be using durasurf (just what we can get our hands on, both are extremely solid options).

If there are any other construction facts people want to know, we are not afraid to add them to the website.

We have plans for topsheet graphics in the future, some sick ones on the back burner, we wanted the first drop to highlight the shape and ride and to focus less on visuals. Thanks for the rec. on the topo.

In terms of pricing, we will sell our skis from our Chinese order, and then when we run out, we will hand build to match any demand, (this is all entirely reliant on demand). All skis are built and tested by us first and exact specifications and even physical skis get sent to china, and to be honest the quality of skis from china in this day in age isn't really a question if you use the right manufacturer. For example, a lot of DPS is made in china and no one bats an eye on their durability. We would want to be made 100% in the USA, but for this first run we wanted the best price to consumer, and frankly no one in the US had room for our order this year, and in my previous comment on us having a US manufacturer, we plan on using them for the following seasons as we are now waitlisted. Also, having multiple options will help us in the future as we expand our line up. K2/Line use like 3 or 4 different factories, this isn't uncommon.

Lastly, the comment about using beefier materials for anything hand made ect. its hard to get hands on any materials right now, so going against the standard is nearly impossible, eventually we want all of our bases and edges to be thicker like a onep, our other materials are already whats best on the market.

hopefully this answers a lot more questions.