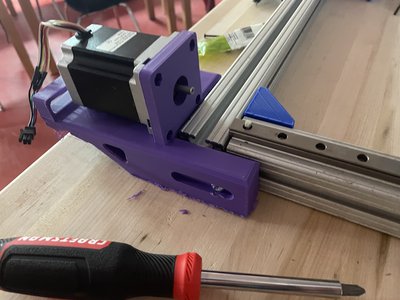

Tested the first prototype of the stepper mount today

Welcome to the Newschoolers forums! You may read the forums as a guest, however you must be a registered member to post. Register to become a member today!

ajbskiIt’s hard to tell what gear is inside from the picture... planetary are the best

but looks ok. I think belt would have been fine for z axis. The x and y should get gears instead of belts

ThegenericskierI was thinking of not putting belts or gears on the X and Y just for speed

ajbskiNot wrong. Precision vs speed has always got me deep in thought.

I’m into reductions for the greater resolution you get. A bigger pitch on the screw helps with speed too

**This post was edited on Apr 19th 2022 at 4:17:22pm

ThegenericskierThat’s a good point, but most of the stuff I’ll be making is not going to require too tight of a tolerance. Gonna add a 1.5 Kw spindle pretty soon. Any tips on getting rid of as much EMI from that spindle?

ajbskiVfd are good if you want to control the spindle and speeds with logic outputs.

the only reason I can think of doing that is for tool changes.

I think you’ll have more luck with getting a nice palm router and just manually controlling power and speeds. At least while you are learning about feeds and speeds.

on a side topic,

They make them with batteries now. I think it would be so cool if there were portable cncs that you could bring to a job site. you could plug into a 12v dc car adapter and the spindle runs off batteries.