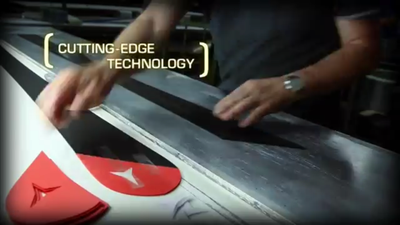

FaunaSkisYes they do just tape different coloured sections together, theyre usually die cut though, not laser. You would think that you might see joins but the people building the skis do it day in, day out, and assuming the QC process is good you won't get skis with noticable gaps between the pieces leaving the factory, it's also helped by tight tolerance molds which wont let you put the base down with a gap between the pieces without causing bigger problems, so the tape isnt really doing a lot, more tacking it in place for the mold.to hold it while the epoxy cures

As to your other question, its unlikely that base you put a picture of is full clear, whats likely is the white and yellow parts are clear base material cut outs that are inserted that is painted on the back side to give you the colour rather than different sections of different colours of bases. It's slighty cheaper material cost to use less base colours and labour cost to only have to insert a single colour material into the cutouts (pre-painting).

so you are saying on these skis the area i outlined in blue is a section of transparent PE on top of a painted layer? Wouldnt there be a slight change of color/texture of the black background going from an opaque black PE segment in the middle of the ski to a transparent PE segment in the blue area?

amccahill93They're called die cut bases and they suck. Worked at a shop for ayears in MT and csnt tell you how many skis I saw come in with what would be a core shot, but instead a whole letter/pattern chunk is missing from their base.

The thing is the opaque black bases are usually faster than transparent/colored bases. All gs sg dh racing skis have opaque black bases for this reason. I read a paper that conjectured that the black base helps with melting the snow or something bc it absorbs solar radiation or something which ends up making black bases faster but for whatever reason they are faster.

probably not much, but enough to make a difference in all races with gate separation wider than slalom.

Its interesting that the seams i am talking about seem to come with issues tho. I was thinking it might leave a seam or gap but from what you are saying that seam/gap actually can be a point of failure and rip out if it snags on a rock etc...

I wish some tribologists would do more gliding friction tests on all sorts of skis to put a concrete number on how fast certain types of bases are relative to one another.