A quick word on blocking ads

It looks like you are using an ad blocker. That's okay. Who doesn't? But without advertising revenue, we can't keep making this site awesome. Click the link below for instructions on disabling adblock.

Welcome to the Newschoolers forums! You may read the forums as a guest, however you must be a registered member to post. Register to become a member today!

BdoobzI mean either would work. The 16 has more metal so it may be a bit more durable. The 13 has more colour options though.

The older school of thought is to be close to the middle of the range, in which case the 16 may be a bit better. That thinking is a bit out of date though.

BdoobzThat thinking is a bit out of date though.

BdoobzI mean either would work. The 16 has more metal so it may be a bit more durable.

aanevI disagree partially (and I might be wrong ):

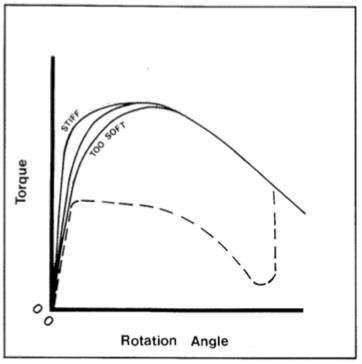

A 16 DIN spring at 10 will behave differently than a 13 DIN spring. And yes, the opening force should be the same. However, the behavior within the travel before opening will be different. The stronger spring will have less preload and steeper graph translating to better elasticity which on the other hand may be desired or not.

ethanshredzThis is the correct answer. It's the same reason that on a mountain bike rear shock it's preferable to run a higher rate spring with less preload. You're minimizing the amount of initial force to overcome before the spring starts to compress, resulting in a smoother and more supple ride. The exact same is true of alpine ski bindings.

aanevI disagree partially (and I might be wrong ):

A 16 DIN spring at 10 will behave differently than a 13 DIN spring. And yes, the opening force should be the same. However, the behavior within the travel before opening will be different. The stronger spring will have less preload and steeper graph translating to better elasticity which on the other hand may be desired or not.

ethanshredzThis is the correct answer. It's the same reason that on a mountain bike rear shock it's preferable to run a higher rate spring with less preload. You're minimizing the amount of initial force to overcome before the spring starts to compress, resulting in a smoother and more supple ride. The exact same is true of alpine ski bindings.

aanevA binding with softer spring and more preload will keep the boot better locked to the ski. In some situations that might be a desired effect, but that also would be harder on the human part of the suspension :)

animatorI was taught like this and it makes sense. You don’t want to over or under extend the spring because it shortens the life and stresses it unnecessarily. Definitely true that it’s an older school of thought but well worth it!

ethanshredzThis is the correct answer. It's the same reason that on a mountain bike rear shock it's preferable to run a higher rate spring with less preload. You're minimizing the amount of initial force to overcome before the spring starts to compress, resulting in a smoother and more supple ride. The exact same is true of alpine ski bindings.

No.QuarterNo. DIN is DIN is DIN

aanev@onenerdykid

Yes - I completely agree on that. Both 13 and 16 bindings release the same (crossing point on the graph).

However, before opening there is some travel:

Tyrolia AAAttack²:

Elasticity – Toe: 30 mm

Elasticity – Heel: 16 mm

Look Pivot 18:

Elasticity – Toe: 40 mm

Elasticity – Heel: 28 mm

The ski boot is moving a lot without actually opening within the elastic travel range and different spring rates will have slightly different behaviour. The difference will be noticeable at the beginning of travel, getting smaller across the elastic travel and disappearing at the moment of release.

aanev@onenerdykid

Yes - I completely agree on that. Both 13 and 16 bindings release the same (crossing point on the graph).

However, before opening there is some travel:

Tyrolia AAAttack²:

Elasticity – Toe: 30 mm

Elasticity – Heel: 16 mm

Look Pivot 18:

Elasticity – Toe: 40 mm

Elasticity – Heel: 28 mm

The ski boot is moving a lot without actually opening within the elastic travel range and different spring rates will have slightly different behaviour. The difference will be noticeable at the beginning of travel, getting smaller across the elastic travel and disappearing at the moment of release.

aanevThat is true only at the moment of release. There are plenty of spring calculators online and you can play with them. The springs are linear so its a piece of cake to calculate the initial force to start moving having the following variables:

1. Travel before release - 16mm (according to http://blistergearreview.com/ )

2. Coil difference - approximately 20%

One might argue that the difference is negligible, but it IS there. MATH IS MATH!

P.S. A small graph is attached. Prove me wrong :)

No.QuarterThis graph is not representative of the argument you are trying to make. Just because you throw arbitrary numbers at a graph doesn't mean you are doing math. I would get destroyed if I showed something like this graph to one of my professors last year, one of his catchphrases was "garbage in garbage out". DIN values are not measurements of force on a spring they are simply relative release values that meet an international standard. Also the elastic travel is not necessarily linear just because the spring is linear. A binding releases through a linkage that compresses the spring. And where the fuck is this 20% number coming from? Again a misunderstanding of the relationship between the force on the spring and the DIN release value. Arbitrary math is not math