It's a pretty straightforward piece to build:

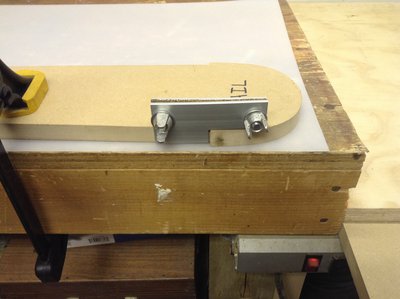

It uses 1" aluminium angle, 1-1/2" aluminium flat strap, two 5/16 thread bolts, two 5/16" thread wingnuts, two washers, some cork and spray adhesive, and it can hold a variety of blades (I personally prefer standard utility knife blades).

Using it is very straightforward. Simply set the knife depth by stacking your ski template on top of some base material at it's edge and with the blade in the tool, loosen the two nuts and let the blade drop to the bench then tighten the nuts. Then clamp your template on top of your base material firmly on a flat bench and draw the knife along the sidecut and tips of the template. A little tip, because of the blade's thickness it will allow the guide to rock side to side, you want the leading edge of the guide to always be flush with the template so it's always steering the blade into the ski.

Around your tips and tails it's a bit trickier, you just have to make sure that the blade is always flush with the template. If the blade accidentally steers away it's okay, because you can go back and pick up the proper cut very easily.

Another thing worth noting for builders who flange their template's tips and tails for 3/4 edges is a variation of the knife made to cut into the corners of the flange.

Basically it has a section cut out of the face, but part of it remains to support the blade and keep it flush with the template. You can get away with using just one of these knives should you be using the 3/4 wrap style edges but you'll have to flip the face plate 180 and reset the knife to get all of the flanged corners. Personally I have two of these so there isn't any changeover time while cutting. Building these extra two knives on top of the main one is well worth the convenience when it comes to cutting out a ski base.

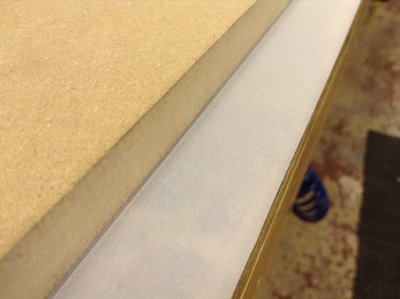

The quality of the cut these produce is the big standout for me. Yeah a flush trim bit and a vacuum template do a fairly nice job trimming bases but if you examine the trimmed edge very closely it is rippled because a router bit makes thousands of tiny, very small radiused cuts to make one big cut. These on the other hand make one continuous smooth cut. I'll try to get some pictures up comparing the two edges and the difference between them within the next few days.

A few other notable benefits are the cleanup as there is absolutely none (although sometimes UHMW snow all over the workshop is kinda fun in it's own strange way), and the better use of material because you're slicing it, not taking a section of it out.

Sorry if that's a crappy post because it's super late at night... But toss some of your questions out there, and I'll try to get a few more pics and details in here. Hopefully it will be useful for a few of you!

Sorry if that's a crappy post because it's super late at night... But toss some of your questions out there, and I'll try to get a few more pics and details in here. Hopefully it will be useful for a few of you!