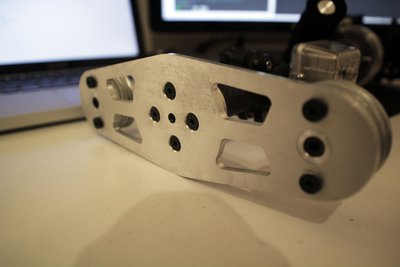

It all started with a $1 bearing purchased from a science and surplus store, it ended up being a machined aluminum, carbon fiber, laser cut metal monster.

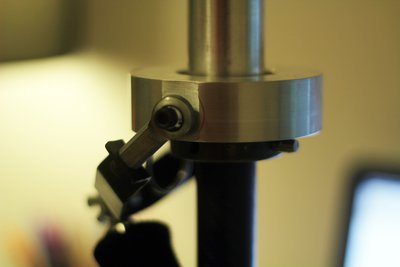

From the initial sketches to drawings on the shop floor, it was a pretty fun project to undertake. Here is the result:

It works pretty slick, I have some footage shot, but I've got to learn how she works, gotta get to know her. I comfortable used it for about two hours and didn't have too much to complain about. Especially when I invested about $100 and $55 of that was for the quick-release plate.

On to the next project!