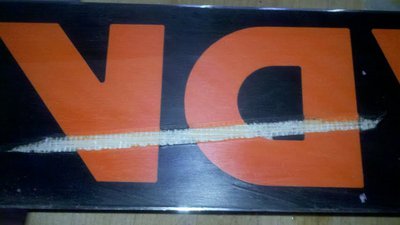

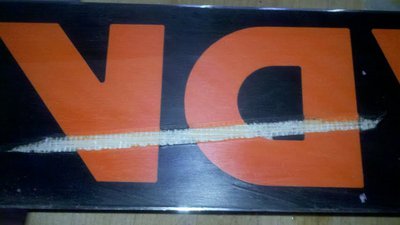

I've done plenty of smaller ptex jobs on my skis but I'm not sure of the best way to go about this this due to its massive size. Any experienced ski techs out there that can give me pointers on how to get the best adherence. Help much appreciated.

Welcome to the Newschoolers forums! You may read the forums as a guest, however you must be a registered member to post. Register to become a member today!

This, except I like to heat up the edges of the base where you're putting the base weld in. It helps the new stuff to adhere to the old stuff if you heat it up unti it starts to look wet first.

But yeah, I'd have a shop fill that. Basewlelders do a much better job than candles but at least it's not on teh edge.